Powder Coating Lab Model Twin Screw Extruder

Product Details:

Powder Coating Lab Model Twin Screw Extruder Price And Quantity

- 1 Piece

Powder Coating Lab Model Twin Screw Extruder Trade Information

- Cash Against Delivery (CAD) Cash in Advance (CID) Cheque

- No

- Contact us for information regarding our sample policy

- North America Middle East South America Africa Asia

Product Description

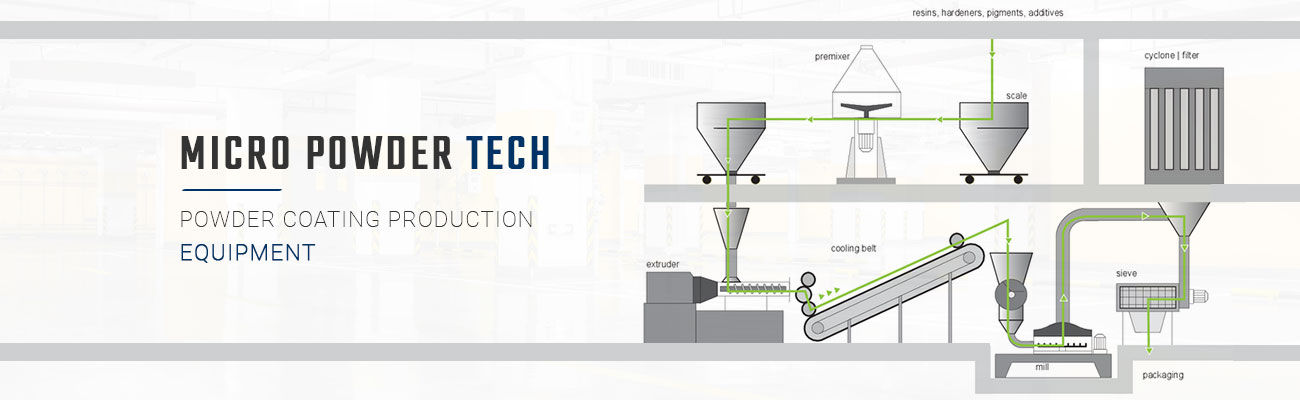

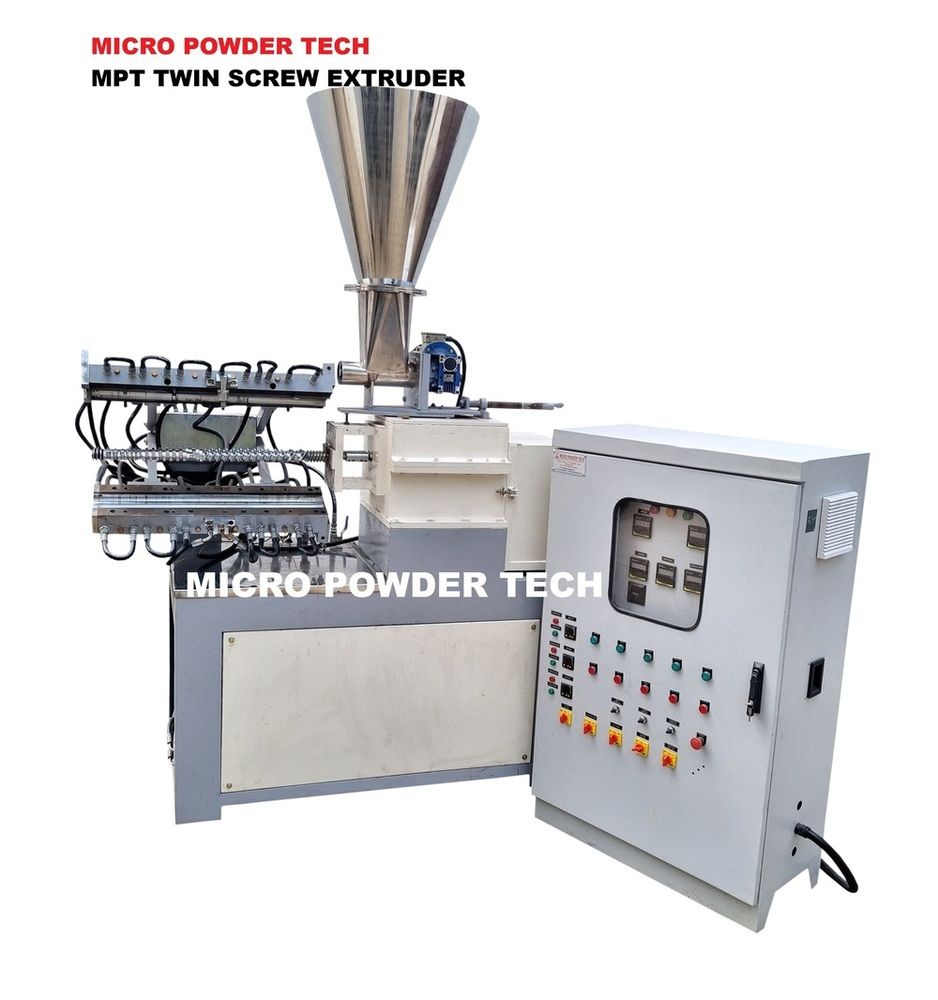

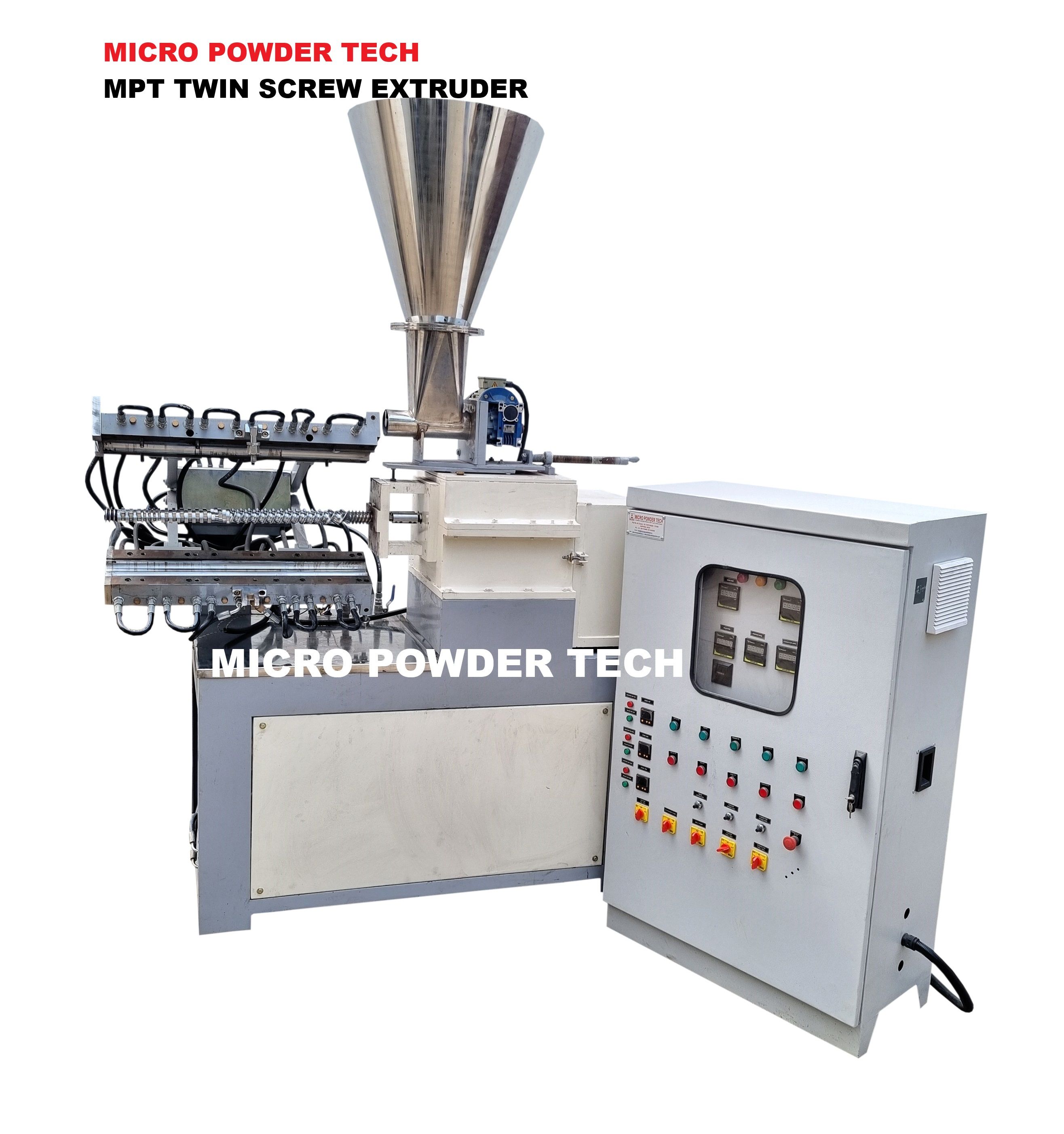

Empowered by advanced manufacturing facility, we are indulged to manufacture, export and supply Powder Coating Lab Model Twin Screw Extruder. The offered extruder is manufactured under the observations of our skilled professionals using quality assured components and modern techniques. This extruder is widely used in various industries for powder coating. In addition, we provide this Powder Coating Lab Model Twin Screw Extruder at affordable prices.

Features:

- Robust design

- Long service life

- Energy efficiency

- Easy to operate

Powder Coating Lab Model Twin Screw Extruder

This product is good for off-line production of small samples. It is ideal for sample that can be manufactured at the rate of upto 10 - 15 Kg./Hr. It is known for production control, research, customer evaluation and color matching. This product is used for the development of new formulations. It is also used at raw materials suppliers for the quality control of pigments, resins and additives. We manufacture this product using wear resistant stainless steel. It is competent of producing Min. 0.400 Kg and 10 -15 Kg./Hr. (Max.) sample. This machine has a clam shell opening barrel and very easy to clean. The temperature is controlled by digital automatic system and the barrel is heated by electric heaters. Plus, the speed of screw can be set according to the requirements.

A unit for the off-line production of small sample. Sample which can be produced at rate of up to 5 - 8 Kg./Hr. need only be a few hundred grams and are typically used for colour matching, customer evaluation, production control and research. The equipment finds application in development of new formulations and at raw material suppliers for the quality control of resins, pigments and additives. MPT-30Lab Twin Screw Extruder constructed of high wear resistance steel and capable of produce upto 5 -8 Kg./Hr. (Max.) and Min. 0.400 Kg. Sample . It has a clam shell opening Barrel and easy to clean. The screw is set variable speed . The barrel is heated by electric heaters and the temperature are digitally auto controlled.

| Technical Specification Screw Dia | L / D | Main Power | Heating Power | Screw RPM | Output |

| 30 mm | 15 : 1 | 3.75 KW | 1.5 KW | 0-400 | Min.0.250 Max. 5-8 Kg./hr. |

Technical Details :

| Product/Model | Twin Screw Extruder with Chill Roll MPT-30Lab | |

| Capacity | Kg/ h | 0.400 Kg Min.- 10 Kg./Hr. Max |

| L/D | | 15:1 |

| Screw dia | mm | 30 |

| Screw speed | RPM | 0-400 |

| Main power | KW | 3.75 KW |

| Drive Type | | AC Frequency Drive |

| Heating power | KW | 1.5 KW |

| No of heating/cooling zones | | 3 zone |

| Heating Type | | Cartridge heaters |

| Screw shaft | | Hexagonal section hard chrome |

| Screw elements | | Feed screw, paddles intermeshing |

| Barrel | | Split type opening, Segmented liner insert. |

| Gear box | | High efficiency |

| CHW flow rate | Lph | 800 Ltrs. / Hr. |

| CHILL ROLLS | ||

| S.S. Chill Roll 2 Nos. | Size | 100 x 200 mm (2 Nos.) |

| Controls & Instrumentation | ||

| PID Control | | PID Controlled 3 Nos. |

| Speed | | AC frequency drive |

| Temperature | | PID Digital temp. |

| Display provided in panel | Screw RPM | Digital Screw RPM Meter |

| | Input voltage | 415 Volt |

| | Current | AMP. Digital Meter |

| | Power | 3Phase indicator, Volt meter |

| Protections (Electrical and Machine interlocks) | ||

| | Drive temp. | Drive internal protection |

| | Motor load | Drive internal protection |

| | Under voltage | SPP |

| | Earth fault | SPP |

| | Mains supervision | MCB |

| | Phase supervision | Digital volt meter, Phase indicator |

| Space requirement | L x W x H, in mm | |

| Extruder | MM | L-1200 X H-1300 X W-500 |

| Assembly weight | Kgs | App. 450 Kg |

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Powder Coating Lab cum Production Extruder' category

|

MICRO POWDER TECH

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |